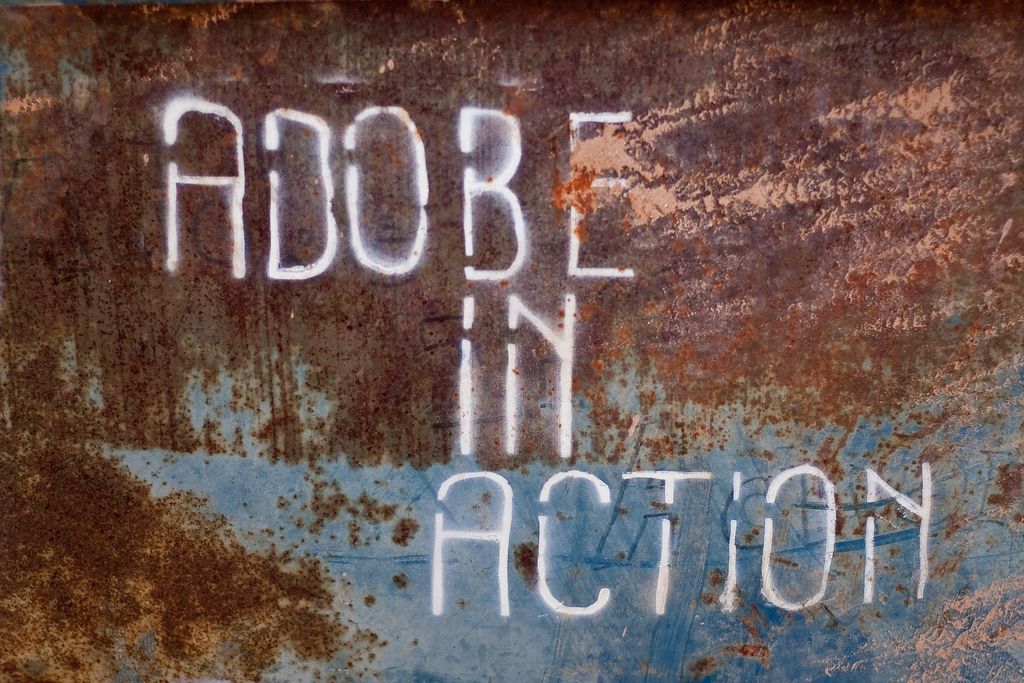

Adobe in Action is a New Mexico-based 501c3 non-profit organization with a global reach. We support owner-builders, practitioners, and communities with the planning, construction and preservation of adobe homes. We promote earthen building and home ownership through education, field-support and diffusion of knowledge.

We provide:

EDUCATION - online & field classes + our biennial EARTH USA earthbuilding conference

OWNER BUILDER SUPPORT - design & building plan consultation + code & permit assistance

FIELD WORK COORDINATION - supporting owner builders with adobe blockmaking, wall construction & natural plastering

Our work:

PROMOTES ECONOMIC INDEPENDENCE - through affordable adobe home construction

BUILDS NETWORKS - through student-supported "adobe raising" activities which directly benefit owner builders and their local communities

PROVIDES EDUCATIONAL LEADERSHIP - regarding the economic, cultural, and environmental benefits of adobe home building and ownership

Upcoming Classes & Events

Adobe Resources & Inspiration

Listen to MUD TALKS to begin your owner builder adobe journey

View our ESSENTIAL ADOBE READING LIST for written resources

Find OWNER BUILDER FRIENDLY SUPPLIERS & SUBCONTRACTORS

See a past OWNER BUILDER SUPPORT PROJECT in Silver City, NM

Learn more about EARTH USA - our Biennial Earthbuilding Conference

See student photos & videos from a past INTRO TO ADOBE PRESERVATION workshop with PAT TAYLOR